Welcome to the new version of our website! We are constantly working on improving it and adding new features. If you run into any problems, please let us know. Thank you for your patience and feedback.

Contact your sales representative and clerk

Product datasheets and safety data sheets

Overview of product stock availability

Educational materials

News about industrial seals

Information on new products and services

Exclusive hints and tips

Fill in your contact details and we will get back to you as soon as possible.

We will call you at your chosen time and advise you on what you need.

Our sales and technical representative will come to your company for a personal consultation.

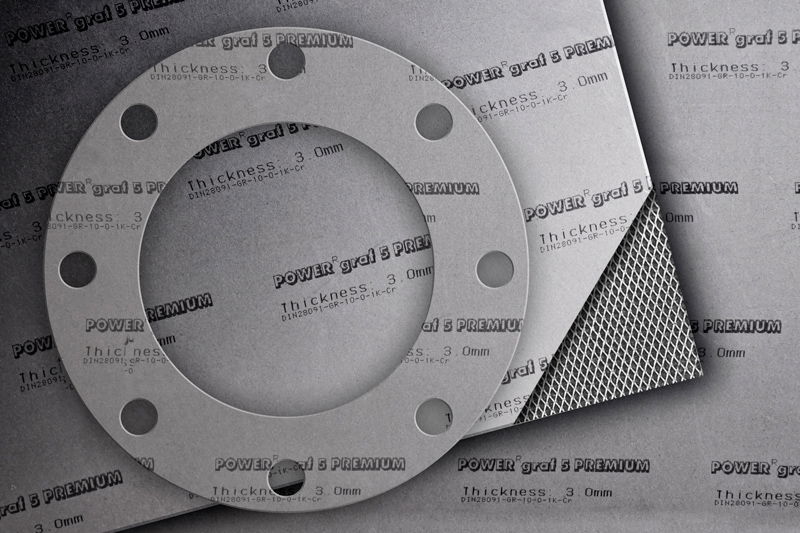

Graphite seals are among the most versatile sealing materials and have the largest temperature range of use, i.e. from -260 °C to 600 °C. They even surpass the still popular asbestos material "Klingerite" in their range of usable parameters. Graphite is a material that does not age and does not lose its properties** with time. On the other hand, they are susceptible to handling and installation. For these reasons, graphite gaskets are reinforced with, for example, perforated sheet or nickel foil.

One of the main parameters for graphite seals is oxidation.

The oxidation, i.e. the loss of material due to temperature and oxygen, results in decreased stress in the bolts, reduced specific pressure on the seal and ultimately leakage of the flange joint.

The quality of graphite and therefore its ability to resist oxidation is determined by the purity of the bearing in which it is mined. Simply put, the higher the chloride, fluoride and sulphur content of graphite, the greater and faster the oxidation of the graphite seal. At the same time, these impurities can cause pitting corrosion on flange sealing surfaces.

The oxidation of graphite seals is detected by the TGA analysis, which works on the principle of weight loss.

TGA analysis test procedure: A graphite sample weighing 2-3 g is first dried at 100°C for one hour and then exposed to 670°C and a 7l/min air flow for two hours. The oxidation value is calculated from the residual weight at the end of the test.

Logically, then, the higher the graphite loss during TGA analysis, the lower the quality of the graphite tested. Unfortunately, on the Czechoslovak market you can also encounter materials whose oxidation ranges from 80% to 99%. So be cautious and ask your suppliers of graphite gaskets for the results of the TGA analysis.

Pokorny Industries Partnership in quality

© Pokorny industries s.r.o. 2024 - all rights reserved

Made by servisdesign