Welcome to the new version of our website! We are constantly working on improving it and adding new features. If you run into any problems, please let us know. Thank you for your patience and feedback.

Contact your sales representative and clerk

Product datasheets and safety data sheets

Overview of product stock availability

Educational materials

News about industrial seals

Information on new products and services

Exclusive hints and tips

Fill in your contact details and we will get back to you as soon as possible.

We will call you at your chosen time and advise you on what you need.

Our sales and technical representative will come to your company for a personal consultation.

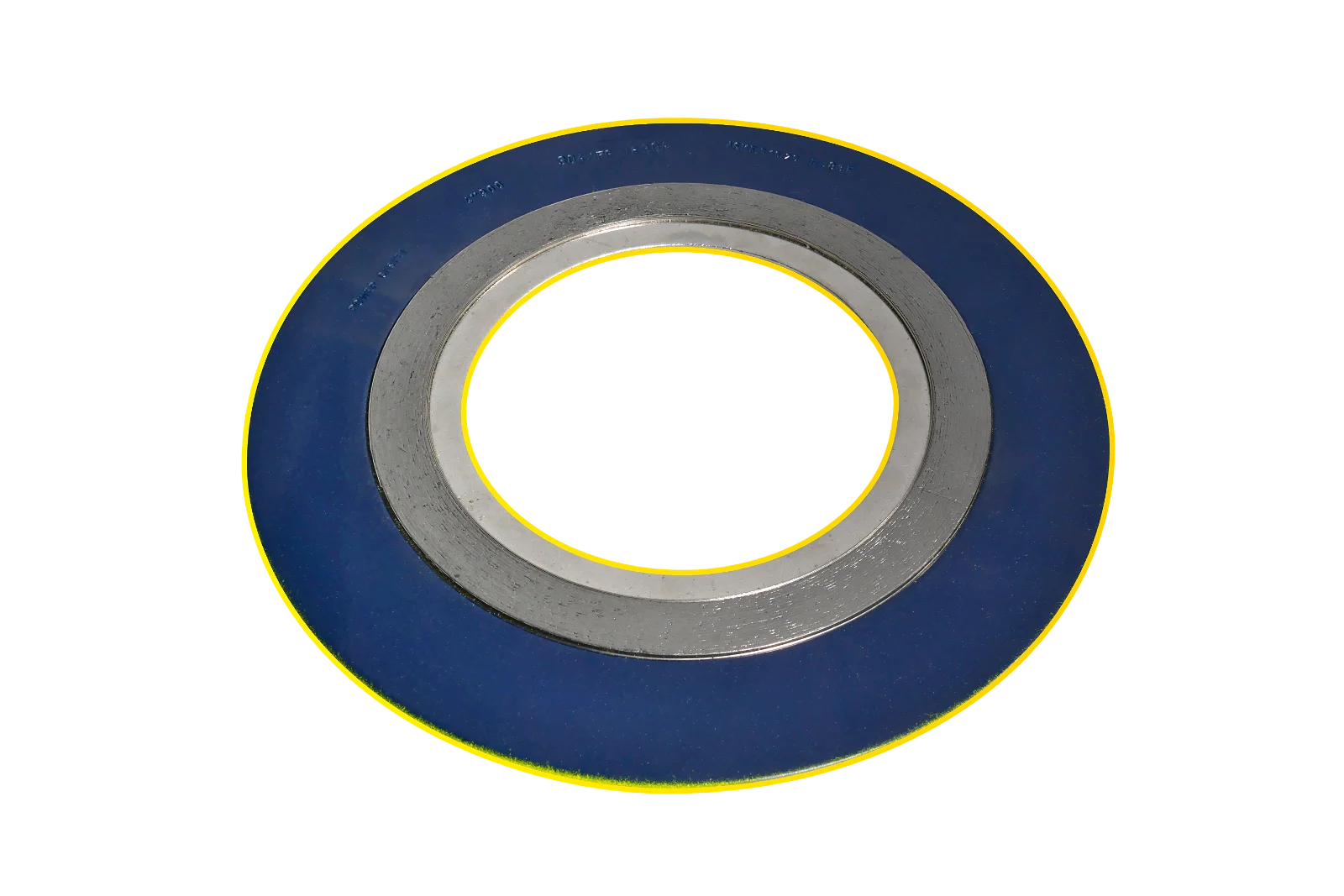

Spiral wound seals are made of various sealing materials in different variants with or without metal auxiliary rings. These seals are particularly suitable for flange joints with variable pressures and temperatures and can withstand temperatures up to 1000 °C depending on the material used.

The inner ring protects the seal material from overheating, impurities from the medium and also reduces turbulence of the medium in the pipe. The outer ring centres the seal in the flange and prevents damage during tightening.

Basic types according to DIN, BS, API and ANSI standards. See the material data sheet for an overview of available dimensions.

| Material | Temperature range (°C) | Max. operating pressure (MPa) | Color of strips |

|---|---|---|---|

| Graphite | -200 to 650 | 20 | grey |

| PTFE | -200 to 250 | 10 | white |

| Mica | up to 1000 | 0,5-5 | - |

| Trade Name | DIN Specification | DIN Standard | AISI | Hardness HB/HV | Temperature (°C) | Specific Gravity (g/cm³) |

|---|---|---|---|---|---|---|

| Iron (LCS) | RSt. 37.2 | 1.0038 | - | 100 - 130 | -40 - 500 | 7,85 |

| Stainless steel. Steel 304 | X5 CrNi 18 | 1.4301 | 304 | 130 - 180 | -250 - 550 | 7,90 |

| Stainless steel. Steel 304 L | X3 CrNi 189 | 1.4306 | 304L | 130 - 190 | -250 - 550 | 7,90 |

| Stainless steel. Steel 309 | X15 CrNiSi 2012 | 1.4828 | 309 | 130 - 190 | -100 - 1000 | 7,90 |

| Stainless steel. Steel 316 | X5 CrNiMo 1810 | 1.4401 | 316 | 130 - 190 | -100 - 550 | 7,90 |

| Stainless steel. Steel 316L | X2 CrNiMo 1810 | 1.4404 | 316L | 130 - 190 | -100 - 550 | 7,90 |

| Stainless steel. Steel 316 Ti | X10 CrNiMoTi 1810 | 1.4571 | 316Ti | 130 - 190 | -100 - 550 | 7,90 |

| Stainless steel. Steel 321 | X10 CrNiTi 189 | 1.4541 | 321 | 130 - 190 | -250 - 550 | 7,90 |

| Stainless steel. Steel 347 | X10 CrNiNb 189 | 1.4550 | 347 | 130 - 190 | -250 - 550 | 7,90 |

| Monel 400 | NiCu 30 Fe | 2.4360 | N04400 | 110 - 150 | -125 - 600 | 8.80 |

| Inconel 600 | NiCr 15 Fe | 2.4816 | N06600 | 120 - 180 | -100 - 600 | 8.40 |

| Incoloy 800 | X10NiCrAITi 3220 | 1.4876 | N08800 | 140 - 220 | -100 - 850 | 8.00 |

| Incoloy 825 | NiCr 21 Mo | 2.4858 | N08825 | 120 - 180 | -100 - 450 | 8.14 |

| Hastelloy B2 | NiMo 28 | 2.4615 | NI 0665 | 170 - 230 | -200 - 450 | 9.20 |

| Hastelloy C276 | NiMo 16Cr 15W | 2.4819 | NI 0276 | 170 - 230 | -200 - 450 | 8.90 |

| Titanium | Ti 99.8 | 3.7025 | - | 110 - 140 | -250 - 350 | 4.50 |

Pokorny Industries Partnership in quality

© Pokorny industries s.r.o. 2024 - all rights reserved

Made by servisdesign